Use Case

Discover how global leaders drive innovation and growth with our next-generation B2B IT solutions.

Join us on a journey of transformation, exploring success stories from multinational corporations.

-

SAP Business One

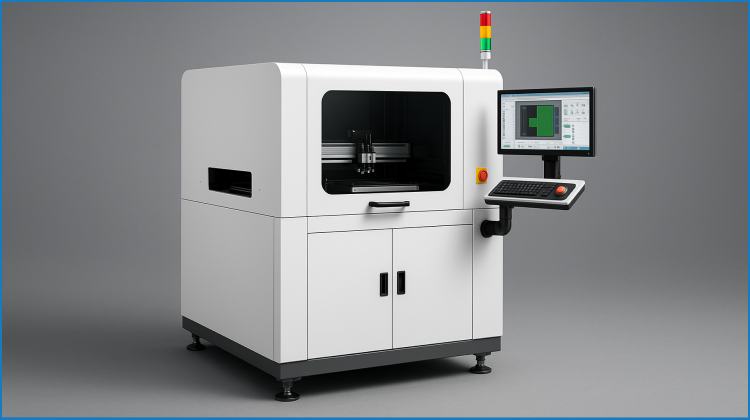

SMT Equipment Manufacturer S | Integrated Information System Implementation Project

2024.08.31.

-

Company Overview

S is a specialized manufacturer of SMT (Surface Mount Technology) screen printers, supplying equipment to key industries including automotive electronics, semiconductors, and displays. With proven engineering capability and a diverse global customer base, the company has continued to expand its footprint. As overseas orders and product variations increased, S required a unified ERP-based operating model to support project planning, profitability management, and end-to-end coordination across production, purchasing, and inventory operations.

Challenges

Operating in a customer-specific, engineer-to-order environment, S faced difficulty analyzing product-level profitability and consolidating performance at the project level. Fragmented departmental workflows created gaps between inventory, purchasing, production, and outsourcing data. A consistent framework to manage project-related material requirements and process flows was lacking. S also needed to ensure data alignment for BOM, work orders, costing, and master codes linked to each order number, while real-time inventory transactions and customer service tracking were inefficiently managed.

Why Woongjin and the Solution were Chosen

S selected SAP Business One for its manufacturing-specific functionality and project-oriented operational capabilities, and partnered with Woongjin to implement W-PMS (project management), W-SCM (supply chain management), C/S management, and integrated inventory tracking. Drawing on extensive ERP and project-based manufacturing experience, Woongjin delivered an integrated solution tailored to S’s ETO environment. W-PMS—Woongjin’s proprietary solution—standardizes material, cost, and profitability management for project-driven manufacturers, while W-SCM connects the entire flow from order intake to material requirements, production, and delivery within the ERP system, significantly enhancing supply chain accuracy and continuity.

Key Results

With SAP Business One integrated with W-PMS and W-SCM, S established a fully connected operational framework where all processes—from material issuance to production, outbound shipment, and revenue recognition—are unified under each project order. Inventory and outsourcing data are now synchronized in real time, improving interdepartmental collaboration and data accuracy. Project-level profitability analysis has become significantly more precise, enabling faster responses to customer customization needs and improving both manufacturing cost visibility and management decision-making confidence.

Project Keywords

#SAPBusinessOne #SMTManufacturing #WPMS #WSCM #ProjectERP #EngineertoOrder #ProfitabilityAnalysis